Creating Wearable Multi-tools

Houdini Sportswear, a swedish high-performance outdoor brand, are constantly pushing the limits of producing high-quality garments with modern minimalistic design and innovative technology while striving towards what has seemed impossible some years ago – a 100% circular production.

We met Eva Karlsson, CEO of Houdini Sportswear, in their FW 2025 showroom in Munich. We spoke about their beginnings and values as a brand, the responsibility of the apparel industry, the importance of circular production, Houdini’s unbreakable desire to learn and, of course, product innovation for FW 2025.

APR MAG: Let’s start with a short introduction – Could you maybe give us some insight on the beginnings of Houdini?

Eva: Well, Houdini wasn’t intended to become a company. It was a bunch of friends who wanted to re-engineer products that suited them better for their expeditions in the late 80s. Back in those days garments were quite bulky and heavy. Full coverage, no stretch. Imagine a mountaineer going on a north face with major altitude differences and weather changes wearing full coverage insulation pieces – you’d constantly get overheated. They would constantly restrict your freedom of movement. If you wanted to put them in your pack, they would take tons of space. All of that needed to be solved.

So, this bunch of friends, mainly Swedish and mainly girls, did precise stretch insulation pieces, covering only those parts of the body at which you’d need more insulation on, so you wouldn’t get overheated. Full freedom of movement.

You wouldn’t have to constantly change. If you wanted to put them in your pack for an expedition, they took way less space than the old garments.

That was the start of Houdini. It was globally unique and it became a company because fellow mountaineers wanted them. Soon after, mountaineering stores, first in the Nordics and then elsewhere, wanted the gear.

It was called Houdini, because Houdini was a house god among climbers and especially within this group.

APR MAG: So that was the start: functional underwear. How did it evolve from functional underwear to high performance outerwear then?

Eva: That’s a good question. I don’t necessarily think the most important and most technical gear is the one that is the furthest out. I would argue against that.

Also, I don’t think a shell layer is not important, but the layers you’re wearing underneath are more important for keeping a stable microclimate and for feeling good. We wanted to continue focusing on that, while also building comfortable layering systems.

When I came on board in 2001, there were technical shell layers and technical base layers, but mid layers were really bulky, still. Combining an average mid layer with a good technical shell layer would still be really uncomfortable – so we wanted to design the perfect mid layer that would fit nicely underneath a technical layer jacket. We didn’t do shell layers back then, but our second step from doing base layers and the precision pieces underneath were midlayers.

That was, when we did the Power Houdi – a very technical fabric. Its design and cut made it fit perfectly underneath the type of technical shell layer that had just surfaced. And from there, we’ve continued developing layering systems for different climates, wearable multi-tools. Not sport specific, but rather the opposite without compromising on performance, of course.

APR MAG: So basically from the inside to the outside. When you look at the today’s outdoor industry and with functional fashion becoming more and more popular, how would you define Houdini’s role within this industry?

Eva: Well, our role or even our obligation is that we promise ourselves to nudge, inspire and to share our knowledge, insights and our way of thinking with all our colleagues in the business, so that we together can transform into something better.

As outdoor brands, we say we love nature, but the relationship is abusive. Nobody works for nature in our industry. That needs to shift. We need to work for glaciers, forests, and for oceans. We cannot continue doing business as usual, compromising with ecosystems, nature, and people in many places of the world. Our obligation and our promise to ourselves is to change that from within, changing how we work.

That has been going on since 2001, when I joined. Reimagining basically everything, not only staying within our own sphere, but rather sharing our way of working so that others can get inspired and join us.

APR MAG: When we connect, when we try to give back to nature, does that also work with product? How does this influence your design process?

Eva: Well, we think about impact in a holistic sense, so we for sure look at how we design a product and which resources go into that. We check which natural resources go into a product, how we can circulate those and we use an existing resource rather than a virgin resource. That is a given, and the same goes for production. How do we produce in a responsible way? Looking at social aspects, ethical aspects and shipping. That is something we really focus on, whereas others only do it somehow but speak about it a lot. We are one of the only brands sharing how many kilos of natural resources we use per year.

When we speak of responsible use of resources, of course we also need to talk volumes. There is a volume issue among outdoor brands, everybody is pushing growth and turnover. It’s our responsibility to think about how we work with volumes in a responsible way. How can we not produce more than demanded. Sometimes that means we produce less than what we could have sold. It also means to design products that enable you to have a smaller wardrobe that does more for you.

It’s also about creating more value for the customer. When I think about all the stuff we have at home, all the equipment, all the gear. Think of helmets, for example. You have different types of biking helmets, climbing helmets, skiing helmets. When it comes to apparel, where we are specialists, we know that there’s amazing opportunities for creating wearable multi-tools, as we call it, where you create a product and the customers buy it for one specific sport, because that’s what we’re used to as consumers. Once you start using it, you’ll realize that you’re wearing it for many occasions. That’s how we design our products, making sure that every everything we create makes sense. Maybe you’ll fall in love with a product and you want to keep it, you want to care for it, and you want to repair it. That’s how we work with volume. It connects to a certain way of life, I guess. How you can have a simpler, more convenient and more fun way of life?

APR MAG: Is there a certain garment that you have never made but wish you had, or that you have made and wish you hadn’t?

Eva: That’s a good question. We did have products in our range a few years ago that we decided to phase out. Not because we didn’t love the performance, we truly loved them and our customers did, too. But we decided to phase out microplastics and microfiber shedding, that is given for many different types of fleece fabrics. We started innovating alternatives that didn’t shed microfibres. I guess that’s an example of acknowledging that we had been doing something wrong. When you have realized that, it’s time to move away and not to wait for somebody else forcing you to do it. I guess PFAS is the same. As soon as we became aware of their impact, we decided to stop using them. We developed a co-created, new fuzz free DWR together with our factories and fabric suppliers and phased out PFAS. That does sound simple, but of course it wasn’t. But it was possible and we did it.

APR MAG: These are probably really big decisions for you as a company, right? Because yes, it does sound simple but also, it requires a major change. Stepping in a completely new direction, how do you make these decisions as a company?

Eva: I think that it’s possible for us to make decisions like that because we believe in our creativity and innovative capacity. We know that we can solve things in different ways. If we had been a company with a lack of trust in ourselves, maybe we would have been afraid to do it. Maybe that’s part of the problem within this industry, people thinking that certain changes are being too complicated or that they would loose money in the end. We’ve experienced so many times that we have the capacity to solve problems and we continue solving them.

APR MAG: Exciting, thank you. Currently, we’re sitting in your showroom for winter 2025. What will be your focus as Houdini in 2025?

Eva: I think that it’s important to not only focus on what’s new, but rather remind ourselves of what is important that might be already there. Another thing is being 88% circular with all our products, meaning that we use resources that are already in place and that can circulate not only once but continuously. That is cool and I don’t think anybody is even close to that. The industry should be and could be though because we share our insights when it comes to circularity. But maybe that’s one of those examples of which others might think it would be too hard.

APR MAG: Circularity means recycled, recyclable or end of life solutions, right?

Eva: Recycled and recyclable. Organic and pure enough to go back into the natural system. These organic fibers or garments can also be retrieved and recirculated in a reuse or remake type of setting. So yes.

If you look at the word circular, it’s used in many different ways. We like to think that nature is circular. Nothing becomes waste in nature. Everything becomes a resource for something else. That’s what we need. That’s where we need to be when we talk about circularity. It does not mean using recycled material for a product which cannot be recycled. That’s not circular. It’s better than doing nothing, but it’s not circular and it’s quite easy to do the opposite. Bring those circular recycled materials into mono-material design, where it can be recycled again and again. That is cool.

APR MAG: That’s super impressive, especially having those 88% as a benchmark that you’ve set and that others need to achieve somehow.

Eva: I think one of the coolest innovations connecting to zero waste and mimicking nature in never creating waste is that we have developed a featherweight mid layer for FW25 that is super soft next to skin, but reminds more of a down sweater.

Imagine if we can make a down sweater that was only made from down. No face fabric, no lining, no bulky seams – only the down. Of course, that’s not possible. But we started developing a yarn that behaves, looks, and feels just like down. It’s a continuous yarn with which we’re knitting the garment directly. No yarn is wasted for a two dimensional fabric that will be cut into pieces and put together. We’re avoiding this step because it creates too much waste. It’s like a down jacket or a down sweater, but without all the elements we didn’t want. It breathes really, really well. You can wear it next to skin and it moves with you. It packs small, so you can bring it everywhere. And it won’t shed microfibres. It can be recycled, it’s made from recycled fabric and it’s recyclable – again and again.

APR MAG: Let’s talk.

Eva: Lykan, it’s called. It’s a sweater with a half zip and a regular sweater, a mid-layer, a balaclava and some other accessories. We’ve developed this yarn in partnership with a Japanese partner of ours.

APR MAG: In general, when it comes to partnerships with manufacturers and using certain fabrics, how do you decide what and whom to work with?

Eva: Well, we have clear challenges that we need to solve on our journey towards 100% circularity and towards regenerative production. We want to become a company that work in symbiosis with nature, every product should work in symbiosis with nature. Of course, that’s a long journey ahead. We are only a fairly small team, so there’s no space for unnecessary product development or innovation. We have tons of work to do in order to reach our vision of becoming regenerative. We identify exactly where we are and where we need to go. Just like nature, we move ahead where we can. Sometimes it’s easier to start with design for longevity, sometimes it’s easier to start with mono-material design, and sometimes you can do both at the same time. We are very uncompromising in our speed and force towards our goal. That’s how we work and we prioritize accordingly. What are the most important things we should do, and where are opportunities to move?

APR MAG: You’ve already mentioned being 88% circular in your production, and it’s one of your key aspects as a brand. Obviously, it hasn’t always been like that. How difficult was it to switch from linear to circular production?

Eva: Well, I guess first of all, we had to gain knowledge and insight on what circular is and on the opportunities for material circularity. We started talking to our partners and suppliers very early about this, it was back in 2001, and they were like: what are you talking about? We were tiny, so it was surprising to them that we would be so clear and stubborn on our wishes. Today, I can say that what the work we’ve done together with these partners has been amazing for us, but also for them, because they have tomorrow’s solutions available today. Not only thanks to us, but thanks to our collaboration and co-creation they have such expertise on material science, machinery, and technology. We have the principles and ideas of where we need to go together. I guess it’s about pushing boundaries towards the next phase to move towards regeneration. There’s always going to be questions that are going to be new to our suppliers, surprising, maybe sometimes even irritating. But then we will move on together, find solutions and it won’t be irritating anymore.

APR MAG: Could you maybe give us an example of one of these collaborations?

Eva: I think Lykan is one, for sure.

APR MAG: How did that work?

Eva: We have an idea, we’re curious and then we start to think as a team. We then partner up with people we like working with. It becomes, you know, a really cool ideation process. Then you get to work and you start testing. You have to be open to failure, because sometimes you fail. Then you have to figure out why it didn’t work and continue. It took some years, but now we made it.

Another example is our shell layers, where we wanted to enhance the outdoor experience, the ski touring adventure. Instead of having a noisy shell layer, we wanted a quiet, soft shell layer that allows you to listen to the mountains, to your friends, to the quietness. There’s a lot of things that don’t have to do with sustainability, but rather just from our standpoint as users imagining what would be cool to have that is not existing. Much like we always did. Our first product was done for mountaineers in the late 80s. That type of thinking is still with us. There’s always things that can change for the better and it’s fun to take on those projects.

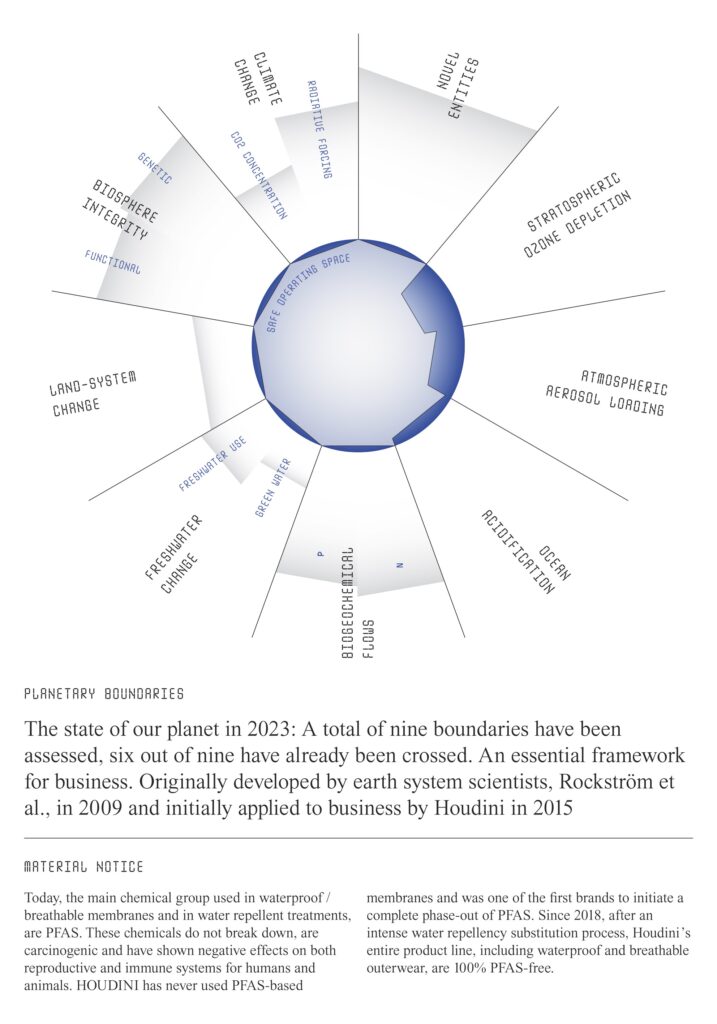

APR MAG: Let’s talk about the planetary boundaries assessment. You’ve currently published your second boundaries assessment. Could you explain to us what it is about and how the initial how the initial idea came about?

Eva: We are on a journey towards regeneration and working in symbiosis with the natural system. This means that we really have to understand this natural system, the complexity of it and the different parameters working together. To do that, you can’t only look at carbon and climate, for instance.

We found this scientific framework that has been developed by earth system scientists. They figured out how to simplify the super complex life support system that we’re part of and that we cannot live without and they came up with a framework that includes nine boundaries. Biodiversity, biochemical flows, the ozone layer, land systems, or ocean systems are boundaries, for example. For us, it made total sense to tap into this scientific knowledge because we could understand the earth’s system better to reduce or even eliminate negative impacts and to potentially have a positive impact in the future. That’s how it started. The framework was there for us to start using. We hooked up with the earth system scientists that had developed it and started exploring how we could improve. I think we were the first company in the world to do so. We wanted to look at assessing our company from a planetary boundaries perspective. How good or bad are we in which areas and how do we move in the right direction from here.

APR MAG: You’ve just published your second assessment. Which changes have you made after the first and what will you change after the second assessment?

Eva: I think there’s not been any U-turns, but we can understand what’s important to focus on. We need to do everything, but some things have a bigger impact than others. We’ve started in 2015 and published the first report in 2018. We then looked at product design and the natural resources that go into our products a lot. We were at the shift from linear to circular production, focusing on product design and production. We learned, of course, to double down on moving from linear to circular, we learned about chemistry and microplastics. It’s not that this was a surprise for us. But looking at chemistry and really working towards green chemistry, phasing out PFAS, solving microplastics – that became an urgent project during the work we did in the report period. When we learn something, we can act on it directly and we have to. So that’s what we did. And then we did the second report.

We have also developed an impact formula – a formula on product production, design, volumes and the lifestyle we can enable. It is something that we’ve realized along the way – a company can move from linear to circular in product design and start using natural, circular, or recycled resources instead of virgin resources and all of that is great – but if we continue pushing out massive volumes of products as we do in the apparel industry today, it won’t help us. We will never become a partner to the natural system. We will exploit it until there’s no natural system anymore, and no human society either. So we need to work on volumes and become much more responsible in how we design product that is versatile and durable.

APR MAG: Was this one of the reasons you’ve established Houdini Circle, you’re garment-renting system?

Eva: Exactly. But it’s also how we design every product. It wouldn’t make sense if we would design a product that you’ll like today, but that is out of fashion tomorrow. Marketing-people try to create trends and anxiety in us so that we feel unsure about which brand to wear for which sport, which silhouette for which season and in which color. All of that needs to be eliminated. With that in mind, we have to design product. How do we make sure that this product ages with beauty? How do we create a color palette that isn’t trendy now and untrendy soon, but rather the opposite? There’s a lot of things in product design, but also in business model design.

APR MAG: What is it that Houdini is currently learning?

Eva: Oh god, there’s so much to learn still. I think that there’s a lot of things that the science community is learning and that we need to be open to. Principles that we as a company have today, might have to be questioned tomorrow due to new insights and knowledge. So being open to that is important.

Going more into depth in terms of materials and chemistry and so forth, on how volumes are important and on empowering people to live a better way of life not only from a sustainability standpoint, but from every standpoint. Creating value in a broader perspective than business, maybe. Cultural shifts for example – how can we support cultural shifts in an individual, a local community, or in a society? We know that it’s part of our responsibility, everyone’s responsibility, but as an outdoor brand, we have the opportunity to do more. How can we become a driver for cultural change? This is something that is much more difficult to measure, but it is so important. How do we contribute to the positive parts of life for individuals, groups, and the society?

APR MAG: Thank you, Eva.